Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In 2026, choosing the best barrier bags for preservation is crucial. These bags offer essential protection against environmental factors. Quality matters when preserving items, from food to electronics. Barrier bags can significantly extend the shelf life of products. They must be durable and effective.

Many factors influence the selection of barrier bags. Consider the materials used. Different materials offer varying levels of protection. Not all barrier bags are created equal. Some might not perform as expected, leading to spoilage or damage.

Reflect on the intended use of the bags. Are they for long-term storage or short-term protection? This impacts your choice. You may need to experiment with various types. Trial and error could yield surprising results. Selecting the best barrier bags requires attention. Aim for a balance between cost and quality. Sometimes, the least expensive option may fall short. Keep this in mind as you navigate your choices.

Barrier bags play a crucial role in the preservation of various products. These bags provide a protective layer that guards against moisture, oxygen, and light. Industry reports indicate that the global barrier packaging market is expected to reach $45 billion by 2026. This growth highlights the increasing awareness of the importance of preservation.

When selecting barrier bags, consider the material. Not all barrier films are created equal. Nylon is often used for its strength, while polyethylene offers affordable options. A good barrier bag can significantly enhance shelf life. Studies show that products stored in high-quality bags can last up to three times longer.

Tips: Always check for punctures before use. A small hole can compromise the entire bag. Additionally, ensure that the seal is airtight. An incomplete seal can invite contaminants. Choosing the right thickness is also key. Thicker bags generally provide better protection, but they can be less flexible. Finding a balance is essential.

When selecting barrier bags for preservation in 2026, pay attention to several key features. Material is crucial. The bags should be made from high-quality film that provides an excellent oxygen and moisture barrier. This preserves the freshness of the contents for longer periods. Look for bags that are puncture-resistant. You don’t want your items to be exposed due to a small tear.

Consider the seal type. Zip locks are convenient for easy access. However, heat seals may provide a stronger closure for long-term storage. Think about size too. Too big and items may crumble. Too small and you might need to cram too much inside.

Tips: Test different sizes before making a bulk purchase. This helps avoid unnecessary waste. Also, store bags in a cool, dry place to enhance their lifespan. It’s worth experimenting with various materials. Not every type may work for your specific needs, so take the time to find the best fit. Remember, it's not just about sealing—it's about ensuring quality preservation.

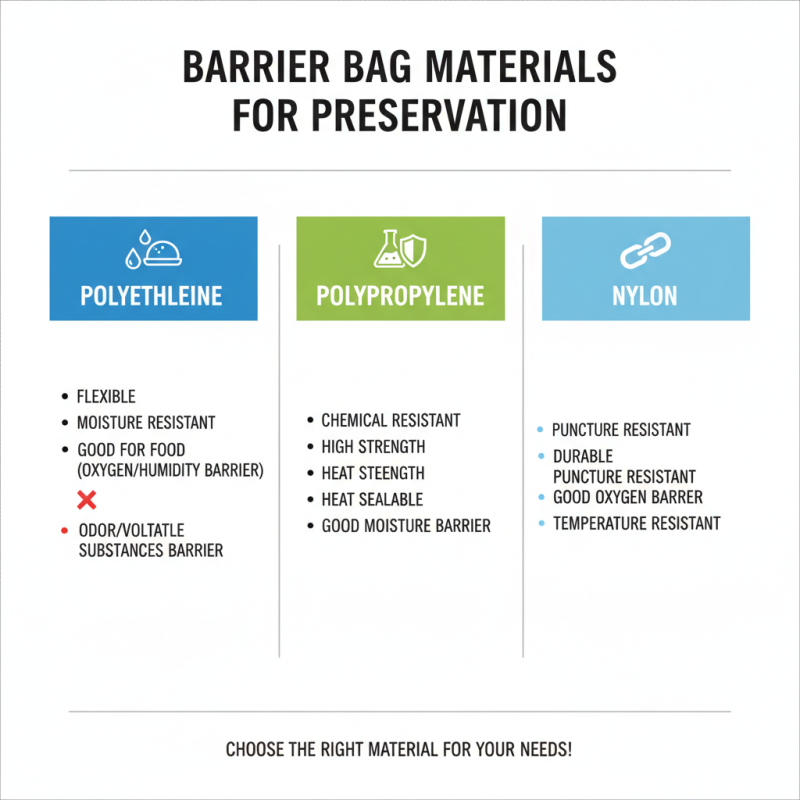

When selecting barrier bags for preservation, the choice of materials is critical. Commonly used materials include polyethylene, polypropylene, and nylon. Polyethylene offers flexibility and is resistant to moisture, making it ideal for food preservation. This material can protect items from oxygen and humidity. However, it may not provide the best barrier against odors or volatile substances.

Nylon, on the other hand, boasts excellent strength and durability. It effectively keeps out gases and moisture, but its higher cost can be a downside. A perfect choice for items requiring long-term storage. Think about sealing methods too. Some bags may not seal tightly, leading to potential spoilage or degradation.

Polypropylene is a lighter alternative, suitable for lighter applications. It resists chemicals but can be less effective in extreme temperatures. Choosing the right material is a balancing act between cost and effectiveness. It’s easy to overlook details like bag thickness, which can greatly influence performance. Often, the best choice isn't obvious and requires careful consideration.

Choosing the right sealing methods for barrier bags is crucial for effective preservation. The sealing method impacts the longevity of products stored inside. With a growing emphasis on sustainability, many manufacturers are focusing on vacuum sealing. This method eliminates air, reducing oxidation and spoilage. Industry reports show that vacuum-sealed items can last up to five times longer than those that are not.

However, not all vacuum sealing is equal. Some techniques may lead to improper seals. This can result in leaks and contamination. A study from the Packaging Industry Research Association highlighted that a 15% seal failure rate can occur due to improper machine calibration. Regular maintenance and proper training are essential to minimize these risks.

Heat sealing is another popular option. It offers a reliable barrier against moisture and microbial growth. However, it requires careful temperature control. Too much heat can damage the barrier integrity. A report by the Food Packaging Technology Institute indicated that 30% of heat-sealed bags tested showed signs of seal degradation after long storage periods. Understanding these nuances can help consumers make informed choices.

| Barrier Material | Sealing Method | Oxygen Transmission Rate (OTR) | Moisture Barrier Properties | Recommended Usage |

|---|---|---|---|---|

| Polyethylene (PE) | Heat Sealing | 125 cc/m²/day | Good | Food packaging |

| Polyamide (PA) | Cold Sealing | 60 cc/m²/day | Very Good | Pharmaceuticals |

| Aluminum Foil | Heat Sealing | <0.01 cc/m²/day | Excellent | Long-term storage |

| Polypropylene (PP) | Heat Sealing | 200 cc/m²/day | Good | Snacks and bakery products |

| PET (Polyethylene Terephthalate) | Cold Sealing | 25 cc/m²/day | Very Good | Beverages and liquids |

When considering barrier bags for preservation, cost-effectiveness and sustainability are crucial. Many options exist, but not all are equal. Barrier bags can offer various degrees of protection, yet their environmental impact is significant. Opting for eco-friendly materials can reduce waste and ensure a better future.

Tips for choosing the best barrier bags:

1. Look for bags made from biodegradable materials.

2. Check the thickness. Thicker bags often provide better protection.

3. Assess the reusability factor based on your specific preservation needs.

Consider the long-term costs associated with using barrier bags. Cheaper options can lead to increased spoilage. This results in additional costs in the long run. Sustainable bags might have a higher upfront price, but they can save money over time. Reflect on your choices. Are you prioritizing immediate savings over the environment?

Evaluate your current practices. Are you using barrier bags correctly? Sometimes, we overlook proper sealing or storage conditions. A small oversight can lead to wasted resources. The goal should be to find a balance between cost and sustainability. Making informed choices is essential as we move into 2026.