Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

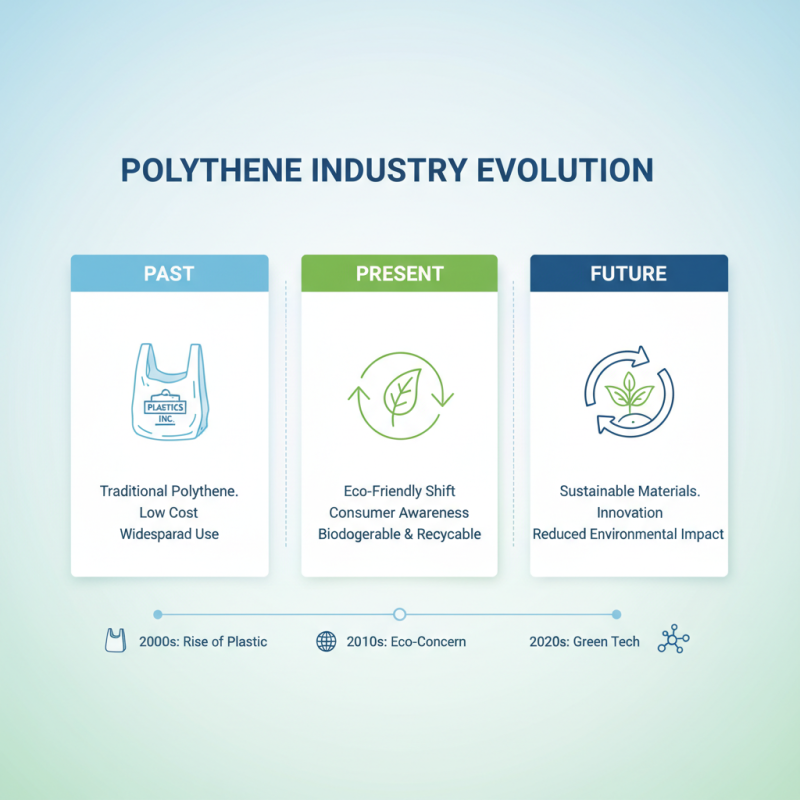

As the world increasingly prioritizes sustainability, the polythene bag manufacturing industry stands at a crucial crossroads. Experts predict that innovative approaches and eco-friendly alternatives will shape the future of this sector, especially as consumer demands evolve. Renowned industry expert Dr. Emily Carter states, "The future of polythene bag manufacturing lies in our ability to innovate towards sustainability, embracing alternatives that reduce environmental impact while meeting market needs."

As we look ahead to 2025, key trends in polythene bag manufacturing will likely focus on biodegradable materials, advanced recycling technologies, and increased transparency in sourcing. This shift not only addresses the pressing issue of plastic waste but also aligns with the growing consumer preference for products that reflect environmental responsibility. The ongoing transition towards eco-friendly alternatives may redefine the landscape of the polythene bag manufacturing industry, prompting significant changes in production methodologies and consumer engagement.

Ultimately, navigating these transformative trends will require collaboration across the industry, with manufacturers, policymakers, and consumers working together to create a more sustainable future. The journey towards eco-friendly alternatives in polythene bag manufacturing is just beginning, and its success will depend on our collective commitment to innovation and responsibility.

The polythene bag manufacturing industry is witnessing significant changes as it adapts to evolving market dynamics and environmental concerns. In recent years, there has been an increased emphasis on sustainability, prompting manufacturers to explore eco-friendly alternatives to traditional polythene bags. The rise of consumer awareness regarding plastic pollution has resulted in a demand for biodegradable and recyclable options, with manufacturers investing in innovative materials that maintain durability while minimizing environmental impact.

In 2025, the market is expected to reflect a clearer shift toward sustainable practices. Many manufacturers are integrating advanced production techniques that utilize less energy and raw materials, resulting in a smaller carbon footprint. Innovations such as plant-based polymers and the use of recycled plastics are becoming more prevalent, aligning with the growing trend of circular economy practices. As legislation around single-use plastics becomes more stringent, businesses are adapting by diversifying their product lines to include environmentally friendly alternatives, while also enhancing the performance qualities of existing polythene products. This transitional approach not only meets regulatory demands but also caters to a more eco-conscious consumer base.

As the global awareness of environmental issues continues to rise, the demand for sustainable alternatives to traditional polythene bags is escalating. Biodegradable and compostable bags have emerged as viable options for consumers and businesses looking to minimize their ecological footprint. Biodegradable bags are designed to break down into natural substances over time, usually within a few months to a couple of years, depending on environmental conditions. These bags often utilize materials like starch or other organic components that decompose in landfills and composting facilities, offering a more environmentally friendly solution compared to conventional plastic.

Compostable bags take sustainability a step further by not only breaking down but also enriching the soil as they decompose. Made from renewable resources such as cornstarch, these bags require specific conditions to compost effectively, including higher temperatures typically found in industrial composting facilities. This process ensures that they fully return to nature without leaving harmful residues. Additionally, consumer education plays a critical role in the effective use of these alternatives, as proper disposal practices can maximize their environmental benefits. As innovation in material science continues to advance, the future of bag manufacturing appears to be leaning towards these eco-friendly solutions, fulfilling both market demand and environmental responsibility.

This chart displays the projected market share of different types of bags in 2025. As sustainable alternatives gain traction, the market for biodegradable and compostable bags is expected to grow, with polythene bags still holding a significant share.

In 2025, the impact of regulations on polythene bag production and usage will be significantly shaped by heightened environmental awareness and governmental initiatives aimed at reducing plastic waste. Countries around the world are increasingly implementing stringent laws and guidelines that restrict the use of single-use plastics, including polythene bags. These regulations are driven by a global movement to protect ecosystems from plastic pollution, which has led to a ripple effect in the manufacturing sector, pushing companies to innovate and adapt their production processes to comply with new standards.

The influence of these regulations will compel manufacturers to explore eco-friendly alternatives, such as biodegradable and compostable materials, as practical substitutes for conventional polythene bags. In 2025, businesses will likely invest more in research and development to create sustainable packaging solutions that not only meet regulatory requirements but also satisfy consumer demand for environmentally responsible products. As a result, the market landscape for packaging solutions will evolve, with a shift towards a circular economy that prioritizes sustainability, reducing reliance on fossil fuel-based materials, and enhancing recycling programs within the community.

The evolution of polythene bag manufacturing is significantly influenced by technological innovations that focus on sustainability and efficiency. According to a report by Smithers Pira, the global demand for sustainable packaging solutions is projected to reach $1 trillion by 2025. This shift is prompting manufacturers to adopt advanced technologies such as bioplastic production techniques and recycled content integration in their processes. For instance, the use of advanced extrusion technology enables the production of thinner, yet stronger polythene bags, thereby reducing the overall plastic waste while maintaining functionality.

Moreover, automation and smart manufacturing technologies are enhancing operational efficiency within the polythene sector. A study by the International Journal of Advanced Manufacturing Technology highlights that automating production lines can reduce energy consumption by up to 30%, which directly impacts the carbon footprint of bag manufacturing. Additionally, the incorporation of Internet of Things (IoT) devices in manufacturing processes allows for real-time monitoring of production efficiency and waste reduction, aligning with the growing demand for transparency and sustainability from consumers and regulators alike. As these technological advancements continue to develop, they are reshaping the landscape of polythene bag manufacturing towards a more eco-conscious future.

As consumer awareness around environmental issues continues to rise, the demand for eco-friendly packaging solutions is poised to transform the polythene bag manufacturing industry by 2025. Recent studies indicate that over 70% of consumers now prioritize sustainability when making purchasing decisions, reflecting a significant shift in consumer behavior. The 2023 Global Packaging Survey found that 65% of respondents are willing to pay more for products packaged in environmentally friendly materials, illustrating a strong market incentive for manufacturers to pivot towards greener options.

In response to this growing demand, the polythene bag industry is exploring innovative alternatives such as biodegradable and compostable materials. A report from the Eco-friendly Packaging Association predicts that the market for sustainable packaging could reach $500 billion by 2025, with eco-conscious products capturing a growing share of the overall packaging market. Companies that invest in research and development of sustainable materials not only align with consumer preferences but also enhance their brand reputation in an increasingly competitive landscape. As regulatory pressures mount, with many countries setting restrictions on single-use plastics, the shift toward eco-friendly packaging is more critical than ever for manufacturers looking to stay relevant in 2025 and beyond.

| Trends | Impact on Consumer Behavior | Percentage of Consumers Preferring Eco-Friendly Options | Forecasted Market Growth Rate (%) |

|---|---|---|---|

| Biodegradable Materials | Higher acceptance among environmentally conscious consumers | 75% | 15% |

| Reusable Bags | Increased purchases of reusable products | 80% | 20% |

| Plant-Based Plastics | Positive shift in purchasing decisions toward sustainable materials | 70% | 10% |

| Edible Packaging | Attraction to innovation and novelty products | 65% | 18% |

| Minimalist Packaging | Preference for simplicity and waste reduction | 72% | 12% |